What is the Purpose of Transformer Oil?

Photo credit: Shutterstock

Transformers are perhaps most known from the movies, action figures, and cartoons, yet in our industry, different kinds of transformers are an integral part of the electric process. These systems are passive electrical devices used to transfer electrical energy from circuit to circuit, both working to decrease and increase voltage levels when necessary. With so much power running through, it’s imperative that transformers are equipped with the necessary equipment to ensure safety and increase productivity. Perhaps the biggest component for this is the transformer oil filtration process.

What are Transformers Used For?

Transformers are critical electrical devices to any electrical process. This equipment boosts voltage levels over long distances, then lowers the voltage levels to decrease line losses during transmission. When these systems begin to fail or deteriorate, however, companies can face safety issues, revenue loss, and certainly higher repair costs. This is why transformer oil diagnostics are so essential, providing you with the data to make informed decisions on your transformer fluid. North Central Electric, or NCE, is a leading provider of transformer oil processing services. Trained by decades of experience and equipped with the latest technology, we provide turnkey solutions for oil processing.

What Is Transformer Oil Used For?

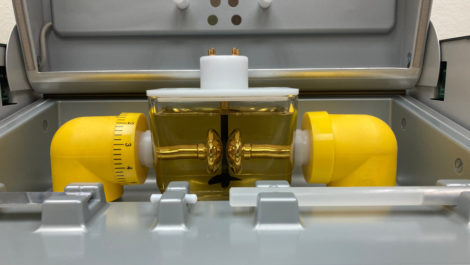

When dealing with such high levels of electrical voltage, transformers and similar equipment require efficient oil that can ease the process and work to combat corrosion. Essentially, transformer oil is used to provide insulation to this high-voltage infrastructure, surrounding its core for protection during the process. The transformer oil filtration process focuses on something known as Breakdown Voltage, measuring the potential dielectric strength of the oil. If there are contaminants within the transformer oil, the Breakdown Voltage will identify a high value to signify this.

The main purpose of transformer oil is to help transformers operate at maximum efficiency, more specifically, to do so at incredibly high temperatures. This includes helping to cool, insulate, and prevent any discharges in the transformation process. The acid found in this oil operates effectively as a cooling agent, reducing heat dissipation by gripping to the windings of the transformer. Without the filtration of high-grade oil, your transformer is susceptible to oxidation and corrosion. Additionally, if the oil is not properly processed by certified technicians, your transformer will gradually lose productivity and effectiveness, costing you money on expensive repairs and causing safety hazards in the workplace.

Trust NCE For Transformer Assembly AND Oil Processing!

With so many complex components and moving parts, NCE provides turnkey transformer solutions to maximize efficiency and take the stress out of your hands. From offloading the transformer at your job site to assembling all its parts, oil processing to final acceptance tests, we provide full-service transformer services for companies in all industries! Combining the area’s most experienced and trained technicians with our own 50-ton crane, line trucks, generators, and more, there’s nobody more qualified for the job than NCE! Interested in learning more or starting your own transformer project? Call NCE today (215) 945-7632!